Compressed Air Pipe Work

Looking for a new compressed air pipe work installation? Please contact us.

We were approached by a client in Bridgenorth to quote to install a full compressed air system into an empty property before they started operations.

The client is in the Automotive Industry and the new site was to be used for the assembly of car bumpers.

We attended site and looked at the air requirements, calculated the required pipe work size and prepared a quotation with drawings.

Whilst on site, we also carried out a site survey to enable us to complete a suitable Risk Assessment and Method Statement specifically for the site.

Our quote was accepted for the compressed air pipe work installation and we arranged for the materials and access equipment to be moved onto site.

The system comprised of just over 700 Meters of stainless steel pipe work manufactured by Isotubi.

The customer agreed with our proposal to use stainless steel pipe as it offers an extremely long life span compared to other metals. There is no corrosion effect from any water vapour that may be present in the pipe work.

We held a short site meeting with our installation engineers and worked out the preferred runs and heights for the headers and runs. This made sure that our installation was neat and all level.

There were two bays to pipe up with three long runs of compressed air pipe work in each bay, connected to a common header at both ends of the building to form multiple rings.

Various lever valves were installed to enable sections of the pipe work to be isolated. This will assist with adding in additional drops and maintenance.

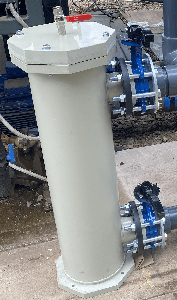

The compressor and receiver were supplied from Atlas Copco and we were asked to install these items.

The main was continued through into the compressor house and we installed this back to the compressor and installed the receiver.

We also fitted a 230v actuated lever ball valve with automatic shut off. The client requested that the compressed air pipe work could be isolated in the event of a fire alarm activation.

The client had Atlas Copco commission the compressor on site to enable the warranty.

On completion of the project we pressure tested the installation and assisted the client with connecting some of the machines.

The system was accepted and signed off by the client. We offered a 5 year warranty with this installation against leaks and defects.

Hamer Mechanical Services can offer a wide range of services and assist you with any compressed air pipe work installation or modifications to your existing system.