Air Handling Unit

Many offices and building use an Air Handling Unit to provide fresh air to offices and rooms.

If equipped, the Air Handling Unit can also extract stale air from the same space.

A heat exchanger of some kind is generally used to transfer heat from the outgoing air, back into the supply air.

An Air Handling Unit requires regular maintenance. Filters gradually become blocked which effects not only the airflow but the overall efficiency of the system.

Hamer Mechanical Services are Air Handling Unit specialists. Please contact us for any assistance with your equipment.

How Does An Air Handling Unit Work?

Fresh air from outside the building is drawn into the Air Handling Unit with a powerful fan, located at the end of the unit.

The incoming air is first filtered through a G4 panel filter. This filter removes any large, airborne particles from the incoming air stream.

Directly behind the G4 filter, an F7 bag filter removes the smaller, finer particles of debris. The F7 filters have a very large surface area compared to the G4 filter.

If the unit provides heat recovery, the air will be pulled through a plate heat exchanger, then transfer to the opposite upper or lower deck. The extraction air also passes through the same heat exchanger, transferring heat in the process. This warms up the incoming air stream to save energy.

The air stream will then be pulled through the fan assembly. Modern AHU’s utilise a plug fan. This backward curved fan is capable of moving very large amounts of air.

Heating and Cooling can be incorporated into an Air Handling Unit to allow the air temperature to be constant.

Large coils are fitted into the AHU that can be fed by chilled water for cooling or LTHW for heating. A DX coil could also be fitted to allow cooling from a refrigeration circuit.

Stagnant return air is extracted from the work space in exactly the same way. Its filtered first to protect the heat exchanger and then discharged outside the building. Heat is removed and transferred back into the incoming air stream (heat recovery).

Some units incorporate a thermal wheel, which transfers heat between the air streams without the use of a heat exchanger.

The Air Handling Unit is generally controlled by a PLC Automation system or building BMS.

By using sensors located in the air stream, the PLC can continually adjust control valves that supply the chilled water and LTHW to the unit.

Where careful control of the building humidity is also required, humidification can be added to the AHU. There are several options to do this including steam injection, wet pressure spray or evaporative pads which are starting to become more common. Evaporative techniques also provide cooling to some degree.

Dehumidification of the supply air can be achieved by using the cooling stage. As the air is cooled, condensation will form on the coil inside the Air Handling Unit. A special tray underneath the coil catches the condense and it falls away to drain. With the water removed from the air, the relative humidity will fall.

Maintenance

Filters require changing regularly at least twice a year. This not only maintains optimal air flow for efficiency but protects the internal heat exchanger from blockage.

All of the fans, motors, couplings and drives should be thoroughly inspected.

Coils should be inspected and cleaned if required. Control valves are operated 0 – 100% to ensure the control actuators are working correctly.

Electronic dampers should be checked and damper vanes, linkages and power motors should be inspected.

All wiring, terminals and connection should be checked to make sure there are no loose connections present.

Finally a check over the door seals, handles and internal lamps if there are any.

Looking for assistance with your existing Air Handling Unit? Why Not Contact Us By Clicking Here

Visit our Electrical / Mechanical Page By Clicking Here

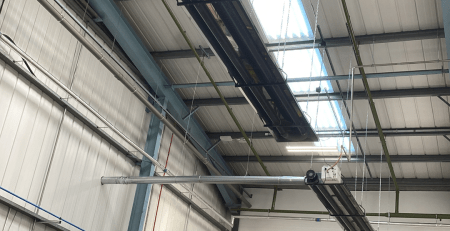

The Air Handling Unit shown in the photos is manufactured by Mark Climate Technology, Click To Pay Them A Visit